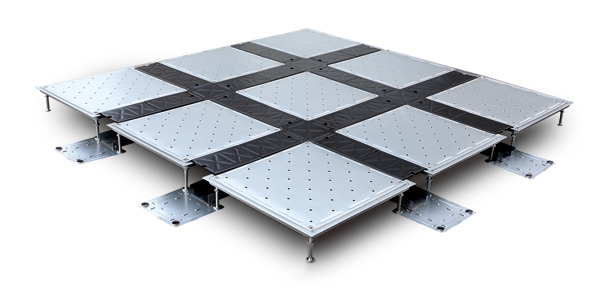

JS508 Hollow Network Floor

Product Details

JS508 hollow floor process description

JS508 type hollow network floor, bottom plate and surface companion adopt the riveting process. It uses a gas-liquid pressurized cylinder and a simple circular concave and convex mold. Through a stamping process, the connected plates can be squeezed into the pressed concave die. Under further squeezing action, the plate material on the side of the punch extrudes the plate material on the side of the die to make it in the die; flow and deformation, so that a perfection without edges and burrs can be produced. Connect the dots. So as to realize a new generation of metal plate connection point technology. Advantages of sheet metal stamping point connection technology: 1. Compared with spot welding, the cost can be saved by about 20%~50%, and there is no connection deformation. 2. The dynamic fatigue connection strength is much higher than that of spot welding. 3. The material is squeezed and strengthened at the connection point without stress concentration. 4. No need to pre-punch, no blanking waste. 5. Does not damage the plating or paint layer of the panel, and the connection point maintains the original corrosion resistance of the panel. 6. Even on the very narrow flange or in a small space, perfect connection can be made. 7. It can easily realize the simultaneous connection of multiple points, with high efficiency and lower cost. 8. The quality of the connection point can be inspected simply and without loss.